Predictive Maintenance for Rotating Machines using Machine Learning Models

Project Overview

This project is aimed at predictive maintenance for rotating machinery by classifying the health conditions of bearings using machine learning models. By analyzing vibration data collected from bearings under different failure conditions, the project detects and classifies faults as:

- Roller failure

- Inner race failure

- Outer race failure

- Combinations of the above failures

Languages & Tech stack

- Python for implementation.

- NumPy & Pandas for data handling.

- Scikit-learn for machine learning models.

- Matplotlib for data visualization.

- SciPy for signal processing.

- Self-Organizing Maps (SOM) for anomaly detection.

- Support Vector Machines (SVM) for classification.

- Artificial Neural Networks (ANN - Multi-Layer Perceptron) for deep learning-based classification.

Methodology

- Data Preprocessing

- Vibration signals are collected using accelerometers at 50 kHz.

- Features are extracted from both time and frequency domains.

- Dimensionality reduction is performed using Principal Component Analysis (PCA).

- Machine Learning Models

- Self-Organizing Map (SOM-MQE) is used for anomaly detection.

- Support Vector Machines (SVM-OvO & SVM-OvR) are used for classification.

- Artificial Neural Network (ANN-MLP) is employed for deep learning-based classification.

Project Snippets

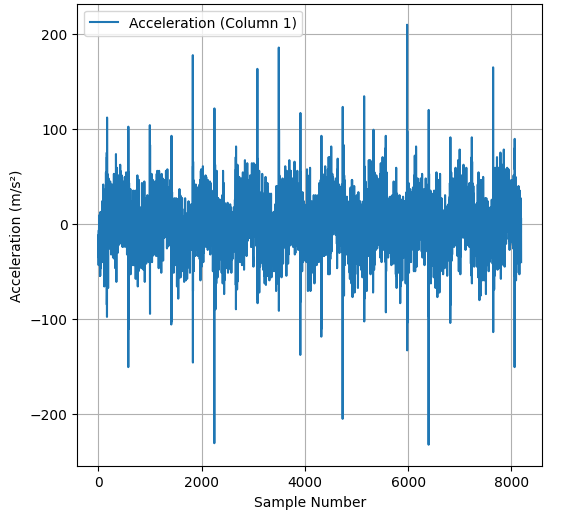

-

Vibration Data Analysis

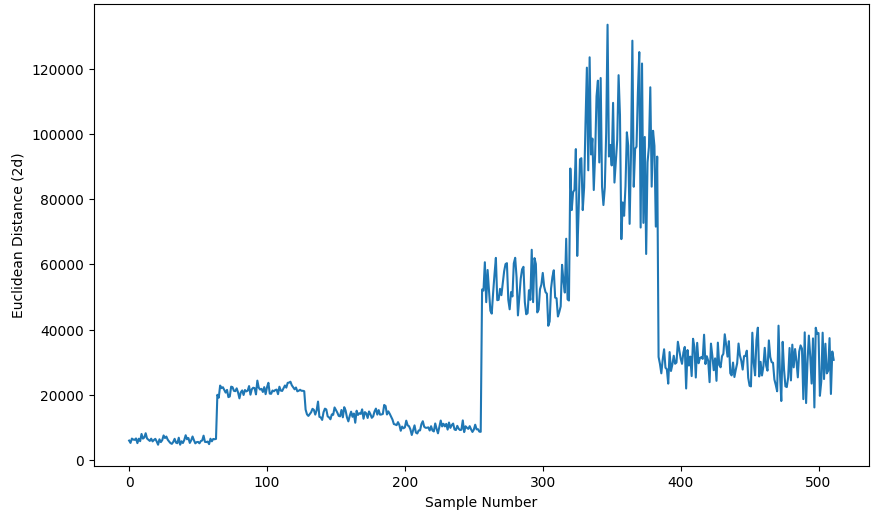

-

Bearing Health Condition Visualization

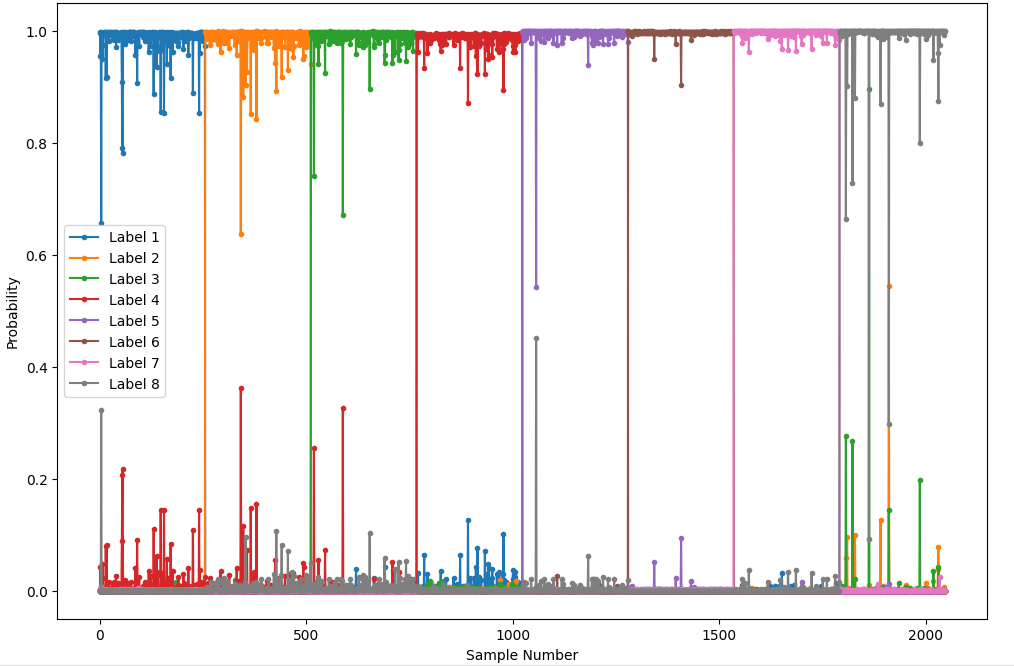

-

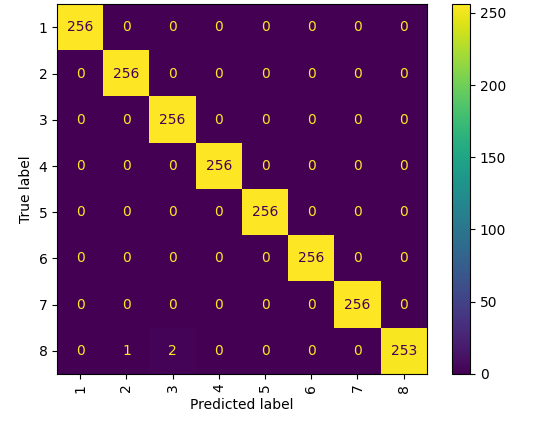

Bearing Fault Classification Visualization

-

Confusion Matrix Visualization